| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

||||||||||

| DYNASTONE® LTD DEVELOPS SOLUTIONS THAT GIVE CEMENT PRODUCTS GREATER BENEFITS, SUCH AS GREATER STRENGTHS, DURABILITY, & ACID RESISTANCE. |

||||||||||

| |

|

|

|

|

|

|||||

|

|

For more general & sales information, contact Dynastone® Corporate Offices at: info@dynastone.com |

|

|

|

For more technical product information, contact Dynastone® Labs at: (210) 684-3322 |

|

||||||||||||||||

| |

||||||||||||||||

|

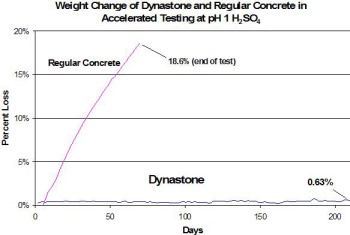

Acid Resistant Concrete Pipe The effectiveness of concrete in wastewater systems is extremely limited due to the corrosive nature of the hydrogen sulfide generated in wastewater. Hydrogen sulfide is generated by anaerobic bacteria in sewage and released continuously into the headspace of the wastewater system where aerobic bacteria convert it to sulfuric acid. Turbulence, warm temperatures and slow flow increase the amount of hydrogen sulfide released and the amount of sulfuric acid produced. Wastewater generates an environment that is both acidic and high in sulfate. Both are challenging environments for concrete! Dynastone® Acid-Resistant Concrete is up to the challenge. In side by side tests with traditional concrete, Dynastone® loses a fraction of the weight as traditional concrete.

Dynastone® has developed and uses an accelerated acid test that is much harsher than concrete is exposed to in actual service. Our accelerated test involves immersing the sample in pH 1 sulfuric acid for 48 hours and then removing the sample and brushing it under running water to remove any passivating gypsum layer. The acid strength is refreshed to a pH of 1 and the sample is again immersed in the acid. A failure is defined to be a total loss of sample integrity or the loss of 25% of the weight of the sample. In actual service, the total loss of strength or the loss of 25% of the weight of a pipe interior would expose the reinforcing steel and result in a pipe failure. As the graph above indicates, the accelerated test results in concrete losing weight at a rapid rate and fails within approximately 100 days. We know of no regular concrete pipe (RCP) installation that failed within 100 days of installation and thus our test is certainly an extremely accelerated exposure condition. So, how long will Dynastone® last? Under the conditions of our accelerated test and extrapolating the weight loss per day, Dynastone® will lose 2.5% of its weight in over 22 years! Under the same conditions, regular concrete lasts much less than 1 year (100 days). In actual service, concrete lasts much longer than 100 days; however, even if regular concrete were to fail within 5 years of installation, Dynastone® should last more than 100 years under the same service conditions. How strong is Dynastone®? Typical physical properties are shown in the table below.

|